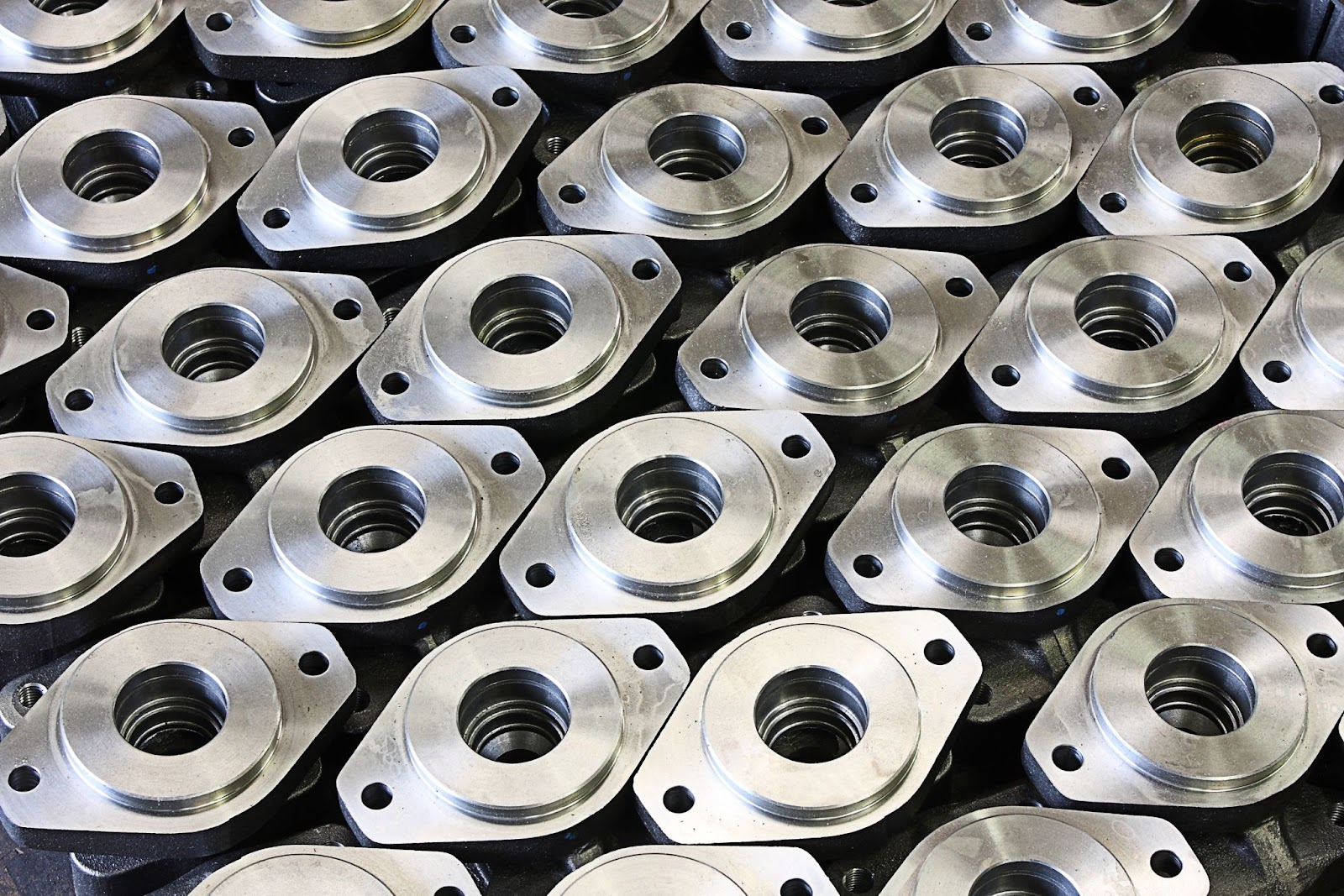

Behind the metal casing of high-end smartphones, the turbine blades of aerospace engines, or the orthopedic implants in the human body lies a core technology revolutionizing manufacturing—CNC (Computer Numerical Control). Acting as the “precision hand” of the industrial sector, it transforms design blueprints into millimeter-accurate physical components, propelling modern manufacturing toward unprecedented levels of accuracy, automation, and intelligence.

What is CNC?

CNC (Computer Numerical Control) is a technology that controls machine tool movements through digital program instructions. Its core principles can be summarized as follows:

Digital Design: Creating 3D models using CAD software.

Instruction Coding: Converting models into G-code (controlling tool paths) and M-code (controlling machine actions) via CAM software.

Automated Execution: The CNC system interprets the code, driving servo motors to precisely control the relative motion between the tool and workpiece, completing operations like cutting, drilling, and milling.

Key Innovation: Replacing traditional manual handwheel operations with computer programs, enabling seamless transformation from design → code → physical part.

How Does CNC Work? Technical Process Breakdown

Using the machining of an aerospace aluminum alloy part as an example:

Programming

Engineers import the part’s 3D model into CAM software.

Define tool paths (e.g., rough grooving → finish contouring) and cutting parameters (spindle speed: 12,000 RPM; feed rate: 5 m/min).

The software automatically generates a program file containing 5,000 lines of G-code.

Machine Setup

-Mount the aluminum alloy blank onto a vacuum adsorption worktable.

-Load a diamond-coated end mill into the tool magazine; a tool presetter automatically measures -tool length compensation values.

-A probe touches the workpiece’s four edges, completing coordinate system alignment in 10 seconds (accuracy: ±0.002 mm).

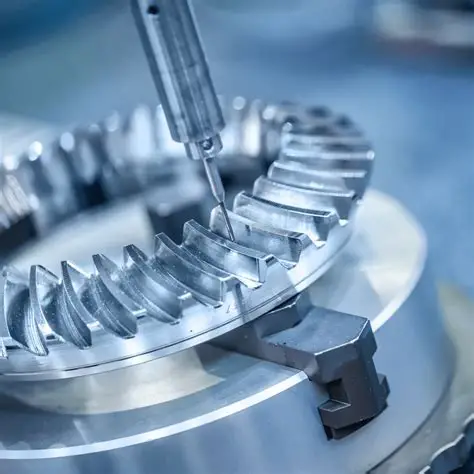

Intelligent Machining

-The machine automatically changes tools, performs cuts, and flushes away chips with coolant.

-Sensors monitor vibration and temperature in real time, dynamically adjusting feed rates.

-5-axis simultaneous motion carves complex aerodynamic surfaces.

Closed-Loop Quality Inspection

An in-machine probe scans critical dimensions of the finished part; data feeds back to the system to automatically compensate for tool wear errors.