CNC machining (abbreviated from “mechanical processing”) refers to the manufacturing process that utilizes machine tools (such as lathes, milling machines, drill presses, grinders, boring machines, etc.) and cutting tools to precisely shape metal, plastic, composite materials, and other raw blanks into parts or products with the required form, dimensions, and surface quality through the physical removal of material. With the integration of advanced technologies like Computer Numerical Control (CNC), high-speed machining, and multi-axis machining, its capabilities, precision, and efficiency have undergone revolutionary improvements, making it an indispensable key link in the modern industrial system. Its main application areas span the core pillars of the national economy:

–Aerospace: The Pinnacle Challenge of Precision and Reliability

- -Core Applications: Manufacturing turbine blades, compressor discs, and combustion chamber components (requiring tolerance of extreme high temperatures and pressures) for aircraft engines; complex structural components for aircraft fuselages (e.g., wing spars, ribs, critical landing gear parts); precision cabins, propulsion system parts, and satellite structural components for spacecraft.

- -Key Requirements: Ultra-high precision (micrometer to sub-micrometer level), complex surface machining capabilities (5-axis machining is standard), ability to process difficult-to-machine materials (e.g., superalloys, titanium alloys, composites), stringent requirements for surface integrity and stress-free conditions. Machining here directly impacts flight safety.

–Automotive Manufacturing: Balancing Mass Production and Performance

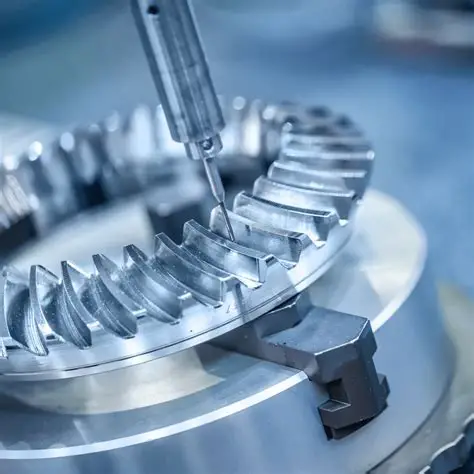

- -Core Applications: Engine core components (cylinder blocks, cylinder heads, crankshafts, camshafts); transmission housings, gears, shaft-type parts; chassis system components (steering knuckles, control arms, brake system parts); precision molds for interiors and exteriors.

- -Key Requirements: Extremely high production efficiency and stability (adapting to assembly line rhythms), excellent cost control capabilities, meeting strict dimensional tolerances and interchangeability requirements, processing various materials (cast iron, aluminum alloys, alloy steels). CNC technology is key to achieving high-volume, high-consistency production of automotive parts.

–Mold Manufacturing: The “Master Mold” for Product Forming

- -Core Applications: Manufacturing precision molds (cores, cavities, sliders, mold bases, etc.) for various processes such as plastic injection molding, die casting, stamping, forging, and glass forming.

- -Key Requirements: Extremely high shape accuracy and surface finish (directly impacting product appearance and demolding), ability to machine complex geometric shapes (freeform surfaces, deep cavities, narrow slots), capability to process high-hardness mold steels (e.g., H13, S136), excellent dimensional stability and longevity. Machining is the core process in mold manufacturing, determining the quality and production efficiency of the final product.

–Energy Equipment: The “Heart” Driving the World

- -Core Applications:

- Traditional Energy: Large power generation units (steam/gas turbine blades, rotors, casings), internal combustion engine key components, oil drilling and refining equipment (valves, pump bodies, complex piping).

- New Energy: Giant spindles, gearbox parts, hubs for wind turbine generators; precision valves, pump bodies, reactor internal components for nuclear power plants; turbine blades, guide vanes, large shaft-type parts for hydroelectric generators.

- -Key Requirements: Capability to handle large/extra-large workpieces, processing high-strength/corrosion-resistant materials, ensuring high reliability and sealing under long-term operation, meeting stringent safety standards.

–Medical Devices: The Precision Art of Life

- Core Applications: Surgical instruments (scissors, forceps, bone drills), implants (artificial joints, orthopedic screws, dental implants), diagnostic equipment core components (precision parts for imaging equipment, endoscope parts), medical device housings and structural components.

- Key Requirements: Ability to process highly biocompatible materials (titanium alloys, stainless steel, cobalt-chrome alloys, PEEK, etc.), ultra-high precision at the micrometer or even nanometer level, exceptional surface finish (to reduce bacterial adhes.