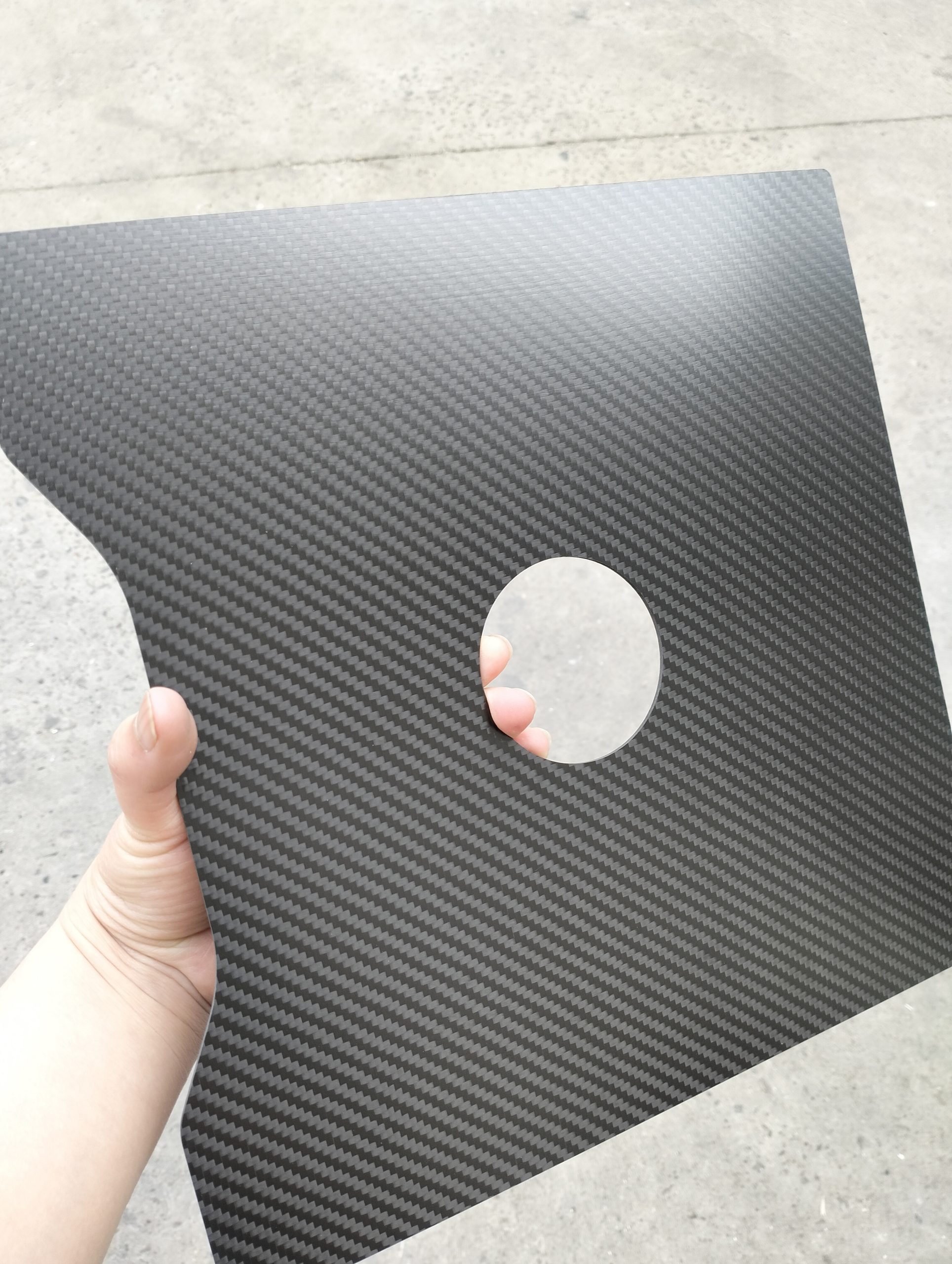

The application of carbon fiber Parts in the auto field is becoming increasingly widespread, mainly reflected in the following aspects

1- Car body(custom carbon fiber parts of car body)

The application of carbon fiber composite materials in automobile bodies can reduce the weight of the body by 40% -60%, equivalent to 1/3-1/6 of the weight of steel structures. For example, the carbon fiber cockpit of the BMW i3 has been reduced by 50%, the General Motors ultra light concept car has a carbon fiber body and chassis that have been reduced by 68%, and the Subaru WRX STItS has a CFRP roof that has been reduced by 80% compared to steel plates. These applications not only reduce the weight of the vehicle, but also improve safety and handling.

2- Automotive wheel hub

The use of carbon fiber composite materials reduces the quality of wheel hubs, helps to reduce the moment of inertia of the wheels, and enables vehicles to have faster starting, stopping, and steering speeds.

3- Braking and transmission system

Carbon fiber Parts composite brake discs can reduce vehicle speed from 300KM/h to 50Km/h within 50m, withstand high temperatures of 2500 ℃, and have stable performance. Custom carbon fiber drive shafts not only reduce weight by 60%, but also have better fatigue resistance and durability

4- Automotive Interior and Doors and Windows

Carbon fiber composite materials have good vibration absorption effect, significant buffering effect on impacts, and reduce the generation of impact fragments, improving safety. In addition, the use of carbon fiber interior and exterior materials not only reduces the weight of automobiles, but also simplifies the manufacturing process of parts, reduces the costs of part processing, assembly, and maintenance, and lowers production costs

5- In the field of intake system and engine(custom carbon fiber tube)

Carbon fiber composite materials, as materials for automotive intake systems, can reduce weight and achieve a lightweight effect; On the other hand, carbon fiber parts materials are easy to process into various curved shapes, and the surface is relatively smooth, which can effectively improve the intake efficiency. The excellent high-temperature performance of carbon fiber enables its application in the field of engines

6- New energy vehicles

In the field of new energy vehicles, the application of carbon fiber composite materials can significantly reduce vehicle weight, improve vehicle power performance, handling, and endurance. For example, luxury brands such as Tesla, BMW, and Audi have all launched new energy vehicle models using carbon fiber composite materials. The application of carbon fiber composite materials can reduce the weight of automobiles by 30% to 60%, and is known as the “king of automotive lightweighting”, leading the “slimming revolution” of new energy vehicles

With the continuous advancement of carbon fiber composite material preparation technology and the gradual reduction of costs, its application in the automotive field will become more extensive. In the future, carbon fiber will not be limited to high-end car models, but will penetrate into the mid to low end market and become the mainstream choice for automotive lightweight technology.

The application of carbon fiber composite materials in the automotive field not only improves the performance and safety of vehicles, but also provides new solutions for lightweight and high-performance design of automobiles, promoting the development of the entire automotive industry towards more efficient, environmentally friendly, and intelligent directions.