When you pick up a carbon fiber bike frame, a golf club, or a sports car component, the first thing you notice is its incredible lightness and sturdiness. Next, you may see its price tag and take a cold breath.

Carbon fiber is known as the “black gold” and is the king of materials science. But why is it so expensive? The answer is not singular, but stems from a perfect storm that combines cutting-edge technology, arduous labor, and enormous energy consumption.

- 1. Starting point: expensive and energy consuming raw materials

Carbon fiber does not exist naturally. Its predecessor was a white synthetic fiber called polyacrylonitrile (PAN). High quality PAN precursor fibers themselves have a high cost, accounting for over 50% of the total production cost of carbon fibers.

But this is just the beginning. To transform these white raw fibers into the familiar black carbon fibers, we must go through a rigorous’ purgatory ‘process:

Pre oxidation: Heating in air at 200-300 ℃ for a long time to stabilize its molecular structure.

Carbonization: placed in an ultra-high temperature furnace at 1000-2000 ℃ under inert gas protection. This process will expel almost all elements except for carbon atoms, forming a strong graphite crystal structure.

These high-temperature furnaces require enormous energy consumption and the equipment itself is extremely expensive. This is a slow, intricate, and energy intensive process.

- 2. The combination of art and science: complex and demanding manufacturing processes

Carbon fiber thread itself is useless, it must be combined with resin to form a “composite material” in order to become a product. This is where the real cost is pushed up.

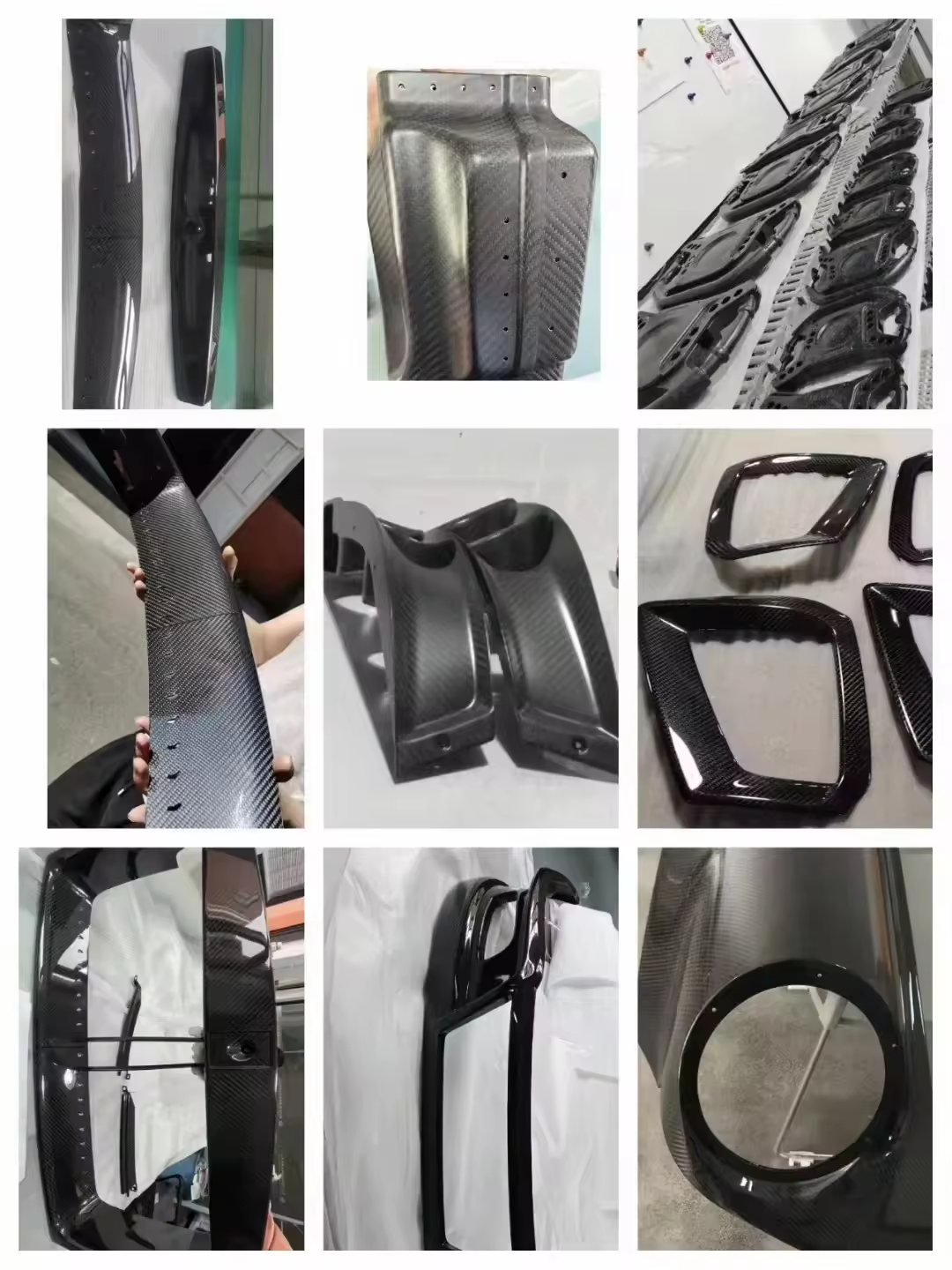

Handmade layering: In many high-end applications such as F1 racing and top tier bicycles, carbon fiber cloth (prepreg) is manually laid layer by layer into the mold by skilled workers. The direction of each layer is carefully designed to provide strength in a specific direction. This is a labor-intensive and extremely time-consuming job that requires superb skills.

High temperature and high pressure curing: After the layer is laid, the mold will be placed in a huge pressure cooker called a hot press tank. The components are cured under high temperature and pressure to ensure uniform resin flow and eliminate all bubbles. The hot press tank itself is a multi million dollar device, and its operating cost is also very high.

High scrap rate: Any minor error in the process – a layer of misplacement, a tiny wrinkle, or inaccurate curing parameters – can result in the entire component being scrapped. Due to the high initial investment costs, the losses caused by these waste products are enormous.

- 3. Invisible costs: R&D and testing

Before you see the final product, a lot of money has already been invested behind the scenes.

Design and simulation: Carbon fiber is anisotropic (with different strengths in different directions). Engineers must use complex computer software for simulation to accurately design the direction of each layer of fibers, maximizing weight reduction while ensuring strength. This requires top-notch professional knowledge and software.

**Rigorous testing: * * Especially in the aerospace and automotive fields, carbon fiber components must undergo countless destructive tests (such as impact and fatigue tests) to ensure absolute safety. These tests are both expensive and time-consuming.

- 4. Insufficient economies of scale

Unlike traditional metals such as steel or aluminum, which are produced in millions of tons annually, the global production of carbon fiber is still limited. It cannot significantly dilute costs through large-scale production. Each carbon fiber product is more like a “high-end customization” rather than a “fast-moving consumer goods on the assembly line”.

Although the price of carbon fiber is daunting, its value cannot be denied:

Extremely high strength to weight ratio: stronger than steel and lighter than aluminum.

Excellent fatigue resistance: more resistant to repeated stress than metals.

Design feasibility: The strength and stiffness of the product can be precisely controlled through layer design.

Therefore, what you are paying for is not only the material itself, but also the top-notch performance, ultimate lightweight, and countless R&D efforts and exquisite craftsmanship behind it. In a sense, the high cost of carbon fiber is an investment in the pinnacle achievements of modern engineering.

If you have any need for custom carbon fiber parts or some need for custom metal /plastic parts by cnc . 3D printing and mould. Pls feel free to contact us for quote .