In the field of advanced materials and composite materials, carbon fiber is undoubtedly synonymous with “black gold”. Among various types of carbon fiber, 3K carbon fiber cloth is the most recognizable and widely used. From the shiny body of supercars to the lightweight frame of high-performance bicycles, its unique checkerboard texture has become a symbol of strength, performance, and modern aesthetics. But what exactly is 3K carbon fiber cloth? What makes it so special? This article will take you to a deeper understanding of all of this.

What is 3K carbon fiber cloth? ——Decrypt “3K”

K “stands for” thousand “, derived from the German word” Karbon “. Therefore, “3K” refers to each bundle of carbon fiber bundles containing 3000 single, extremely fine carbon fiber filaments.

Single fiber: much thinner than human hair, its sexual energy comes from the graphite crystal structure formed by special treatment at high temperatures.

Tow: These thousands of fibers are bundled together to form a bundle, which serves as the basic unit for production and weaving.

Weaving into fabric: These bundles are woven into various patterns of fabric, with the most classic being 2×2 twill weaving.

This high fiber count bundle achieves a perfect balance between flexibility and strength, making it an ideal choice for manufacturing complex shaped parts.

Excellent characteristics of 3K carbon fiber cloth

The reason why 3K carbon fiber cloth is highly regarded is due to its impressive series of physical properties:

Extremely high strength to weight ratio (specific strength): This is the most famous characteristic of carbon fiber. 3K carbon fiber components provide strength comparable to or even higher than steel, yet weigh only a fraction of steel. This is crucial for any application that requires weight loss and improved efficiency, such as aerospace and automotive.

Excellent stiffness to weight ratio: Carbon fiber has extremely high rigidity and can resist bending and deformation, ensuring that the structure maintains its shape and integrity under pressure.

Excellent durability and fatigue resistance: Unlike metals that fail under repeated stress, carbon fiber composite materials have excellent fatigue resistance, making them ideal for components that can withstand sustained vibration or load.

Low thermal expansion coefficient: Carbon fiber maintains almost constant size under temperature changes, making it highly valuable in precision engineering that requires high dimensional stability.

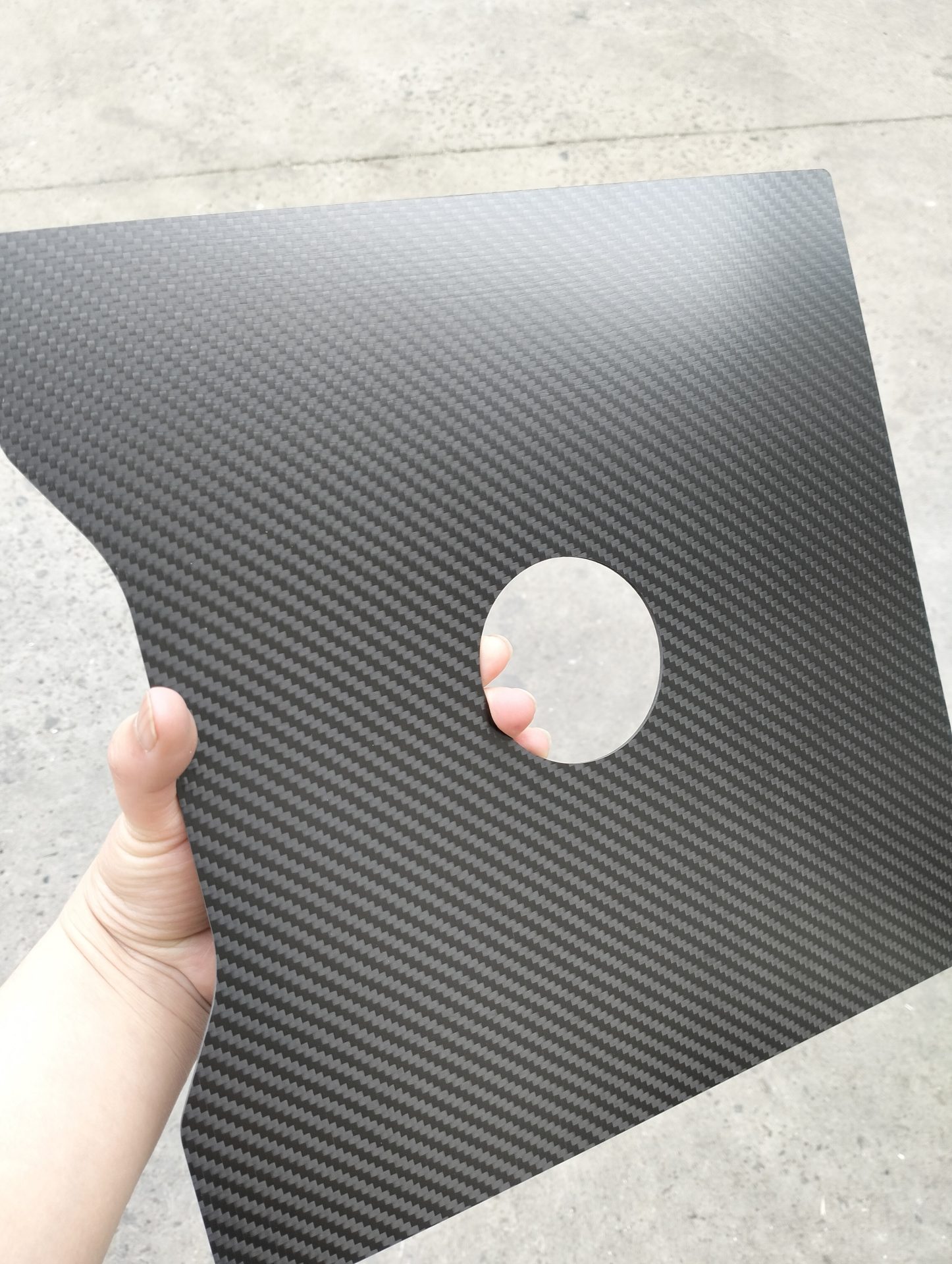

Aesthetics: The unique black twill weave pattern has a high-tech and luxurious aesthetic, usually used as a design element for visible carbon fiber components in finished products, without the need for additional painting.

Classic twill weaving: the combination of aesthetics and performance

The most common weaving method for 3K carbon fiber cloth is 2×2 diagonal weaving. This weaving method refers to a pattern where a strand of yarn is interlaced every two strands along the warp and weft lines, forming a distinctive diamond pattern.

Advantages:

Excellent formability: twill woven fabric has good drape and can be easily wrapped around complex curves and molds without wrinkles or distortions.

Strength balance: It provides relatively balanced mechanical properties in the warp and weft directions.

Aesthetic: Its surface pattern is the most well-known and beloved carbon fiber appearance among the public.

Other weaving methods such as plain weave and satin weave are also used for specific applications, but 2×2 twill 3K carbon fiber cloth is the best choice for achieving a combination of performance and aesthetics.